The RebaGuard™ Galvanic Anode

The RebaGuard system is a discrete embedded sacrificial anode applied to reinforcing steel in both concrete patch repairs and cast into new reinforced concrete elements. The technology provides additional protection and assists in reducing long term maintenance costs against future corrosion.

RebaGuard™ anodes are an embedded galvanic anode encapsulated within a specially designed activating cement-based mortar, once installed the zinc anode corrodes preferentially to the surrounding steel protecting the reinforcement from further corrosion damage.

Additional Benefits

- Traditional embedded Galvanic protection for use in patch repairs and cast into new concrete elements

- Proven Technology

- Low Maintenance

- No monitoring required

- No external power Source required

- Manufactured in the UK to ISO9001

- Up to 20 years protection

- Suitable for both conventional reinforced and pre-stressed concrete elements

- Extends the life and serviceability of the structure

- Reduces maintenance costs

Problem

RebaGuard™ prevents the two main types of corrosion found in reinforced concrete structures

Carbonation induced – exposure to atmospheric carbon dioxide combined with prolonged contact to sufficient moisture and oxygen can leave steel vulnerable to corrosion.

Chloride induced – if chloride in the form of inherently mixed set accelerators or external aggressive salts permeates reinforced concrete in sufficient quantities, an aggressive form of corrosion can be initiated.

The corrosion and its effects often propagate very quickly – so it is crucial to be proactive in assessing and repairing the issue to protect the structure and maintain its asset value.

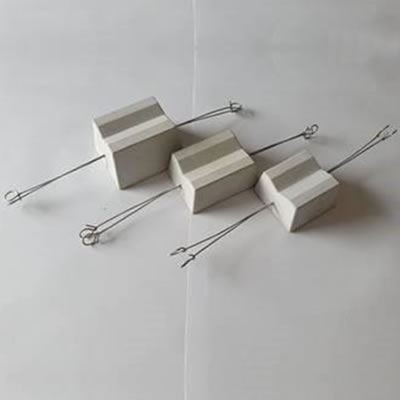

RebaGuard™ Anodes

RebaGuard™ counters corrosion adjacent to the patch following patch repairs. Protective current is delivered directly to the steel adjacent to the RebaGuard unit.

Installation -Concrete repair

RebaGuard™ anodes are installed into the perimeter of patch repairs through the breakout area. The RebaGuard™ anodes can be positioned and tied to the prepared steel using the attached 4 stainless steel connecting wires and encased with a low resistivity repair material to facilitate current flow. Concrete or mortar replacement repairs can then be carried out at any time after the encasement of the anode installation. The location and spacing of the units shall be as specified by the design consultant or with reference to the manufacture’s galvanic spacing guide.

Installation – New Concrete Elements

RebaGuard™ anodes are installed on to the reinforcement steel prior to concrete placement at site or at the pre-cast facility. The RebaGuard™ anodes can be positioned and tied to the steel directly using the attached stainless steel connecting wires. The location and spacing of the units shall be as specified by the design consultant or with direct contact with the manufacturers.

| Product | size | Zinc weight |

| RebaGuard | 55mm x 55mm x 35mm | 60g |

| RebaGuard Plus | 70mm x 55mm x 35mm | 108g |

| RebaGuard Ultra | 70mm x 60mm x 45mm | 180g |

How it works

This system is a traditional method of attaching embedded galvanic anodes to exposed steel in the patch repair. Concrete shall be removed from around and behind the corroding reinforcement in accordance with good concrete practices. The steel shall be cleaned and prepared prior to installing the RebaGuard anode and checked to ensure electrical continuity of the steel and anode to steel. If encased with a low resistivity repair material to facilitate current flow. Concrete or mortar replacement repairs can then be carried out at any time after the encasement of the RebaGuard anode unit.

Once the anode is encapsulated in mortar, protective current flows from the anode to the steel reinforcement. The RebaGuard anodes are placed adjacent to the edge of repairs such that current flows to protect the steel outside the repair area